🏡📦 Now shipping from our UK warehouse — Fast & Free delivery from £100 😉

LAFUMA MOBILIER JOINS PEUGEOT FRÈRES INDUSTRIE

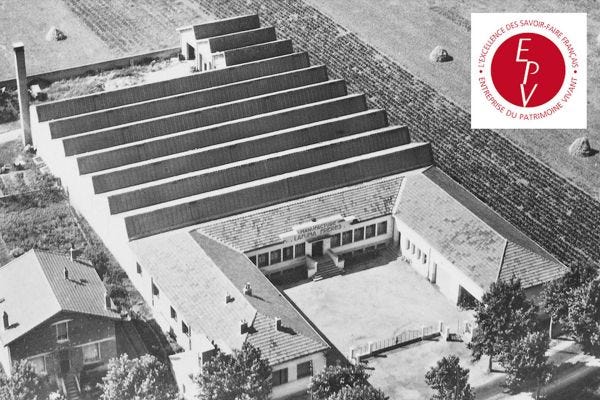

LAFUMA MOBILIER, French manufacturer of outdoor furniture since 1954, has been owned by the Swiss group CALIDA since 2014. The company has now entered into exclusive negotiations for the sale of its shares to PEUGEOT FRÈRES INDUSTRIE, a company 100% owned by the family holding Établissements Peugeot Frères.